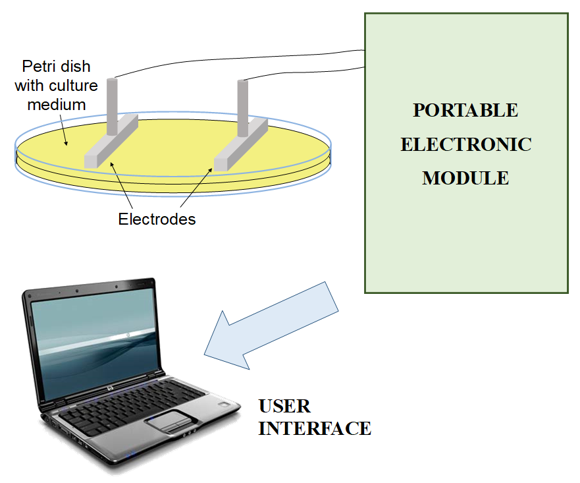

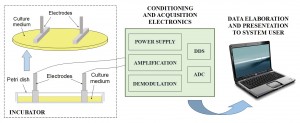

Bacterial infections still represent one of the principal causes of disease (if not death) in both developing and developed countries. For this reason, the early detection of an infection is fundamental for patient’s health, since it permits a more effective action through a suitable therapy. The market offers very advanced systems that carry out preliminary analyses on biological samples, to diagnose the presence of bacteria. An example is the WASPLab (WASP means Walk-Away Specimen Processor) platform, which is commercialized by company COPAN Italia S.p.A. This platform monitors the activity of bacterial cultures inside a container, such as a Petri dish, by taking periodic images of it. Furthermore, it manages all analysis steps, i.e., container inoculation with a pathogen, incubation at ideal growth conditions, and image taking, processing, and storing, in a fully automated way. This activity aims at designing, realizing and testing a sensor system that could be integrated in the WASPLab. The activity has two goals. On one hand, realized system should provide quantitative data about bacterial growth, which could enrich the information coming from image processing. This could augment WASPLab smartness and flexibility. On the other hand, it should present a signal including enough data to anticipate image information. This could guarantee an even earlier objective response about infection, which is critical for patient’s health. As it has been designed so far, the system measures the electrical impedance associated to a Petri dish equipped with an electrode-based sensor. Then, it provides quantitative data about bacterial growth to the user in real time. It permits either a single or a continuos and automated measurement. Furthermore, user can set measurement parameters according to his/her needs. This gives the system a high level of flexibility. This activity is carried out in collaboration with COPAN Italia S.p.A. and other research group from the Department of Information Engineering, University of Brescia. It was part of Adaptive Manufacturing Project (CTN01_00163_216730), which is financed by the Italian Ministry of Education, Universities and Research, through the Cluster Tecnologico Nazionale Fabbrica Intelligente.

a

For more info, please contact Paolo Bellitti, Michele Bona, or Mauro Serpelloni.

a