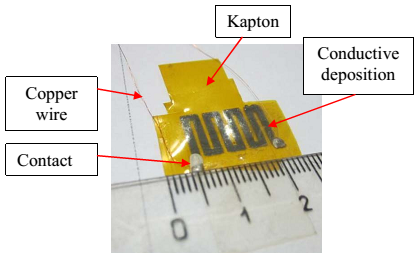

The goal of this activity is the design, fabrication and test of low-cost sensors for biomedical applications. Considering the application field, they should be thin and flexible, in order to fit body’s different parts. Furthermore, they must be made of biocompatible materials. Low-cost inkjet printing is the technology chosen for this purpose. Inkjet printing process is based on the emission of a fixed quantity of a functional ink in liquid phase through printer nozzle. Ink exits in the form of microscopic droplets, which fall on a substrate of proper material. Ink emission pattern follows the drawing of the object that has to be printed. Such drawing can be realized with a common CAD software. Ink solidification can occur by crystallization, chemical modification or solvent evaporation. A post-processing step is often necessary, such as sintering or thermal annealing. So far, sensors for strain measurement have been fabricated. They are characterized by a resistive transduction principle. Design constraints have been investigated. A silver nanoparticles and PEDOT/PSS-based ink and a Kapton substrate have been employed, after having analyzed their properties and assessed their compatibility with used printer. In addition, the behavior of realized sensors has been studied, in order to estimate their gauge factor. This research activity is carried out in collaboration with the Universitat Politècnica de Catalunya (UPC). BarcelonaTECH, Barcelona, Spain.

a

For more info, please contact Michela Borghetti or Mauro Serpelloni.

a